Research

Sustainable Carbon Transformations for a Greener Chemical Industry

Our vision is to foster a sustainable and decarbonized chemical manufacturing industry, harnessing plant biomass and renewable energy, through innovations in biomass utilization, catalyst design, electrosynthesis, advanced manufacturing, and performance materials.

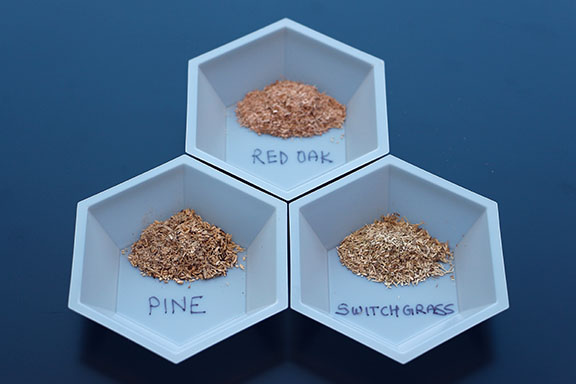

Biomass

Biomass is an abundant source of renewable carbon that has the potential to replace fossil resources as a raw material for chemical manufacturing. Research has already unlocked the conversion of cellulosic sugars to large-volume and low-cost commodity and specialty chemicals. However, the valorization of plants’ lignin fraction remains hampered by its intrinsic heterogeneity and recalcitrant nature. New technologies must be developed to facilitate its recovery and use as a feedstock for chemical manufacturing.

Our Research

Catalyst Design

Catalysis is key to the chemical industry as it enhances the rate of desired transformations, therefore facilitating the formation of desired products while minimizing waste. Researchers continuously improve catalysts by tailoring their structure and elemental composition. One design strategy consists in dispersing the active material—like metal nanoparticles—on a porous support. However, conventional oxide supports developed for petrochemical reactions undergo hydrolytic attacks and irreversibly degrade in water, which is the green solvent of choice for the thermo- and electrocatalytic conversion of biomass. New materials that overcome this limitation are needed.

Our Research

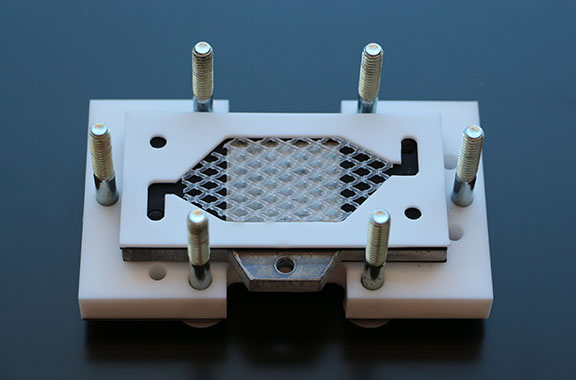

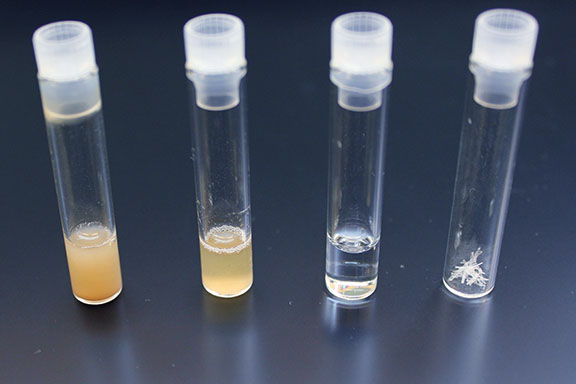

Electrosynthesis

The electrification of chemical transformations is emerging as the next frontier in chemical manufacturing. In contrast to conventional reactions that are governed by temperature, electrochemical transformations are also driven by electrode potential. This potential can be tuned to alter the energetics of the involved species and open new reaction pathways. The opportunities are unlimited: challenging reactions proceed at room temperature, reductive and oxidative transformations can be coupled to achieve energy-neutral processes, new chemical intermediates and products become accessible. This technology also enables the emergence of a sustainable chemical industry that converts a renewable raw material, biomass, using renewable wind and solar energy.

Our Research

Advanced Manufacturing

Present efforts to decarbonize the chemical industry and improve its sustainability focus on replacing fossil fuels as a raw material and energy source. While important, this direct replacement strategy does not capture the specificity of biomass and the many opportunities this feedstock has to offer. One key advantage of biomass over fossil hydrocarbons is the possibility of using biocatalysis—fermentation—and the power of microbial cell factories for manufacturing products that are technically and economically challenging to access using conventional chemical catalysis. These products, including novel molecules, will enable innovations in biodegradable plastics and performance materials.

Our Research

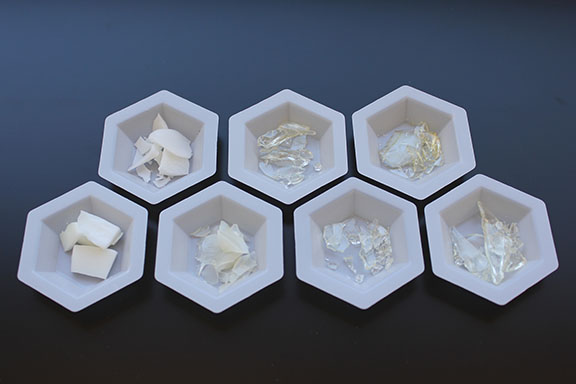

Performance Materials

Innovations in most sectors—communications, transportation, energy production and storage, home goods—are driven by progress in materials synthesis. However, few revolutionary materials have been commercialized over the past decade, and in most cases improvements come from changes in additives and formulation. Additives like dispersing agents, emulsifiers, defoamers, and corrosion inhibitors are common in paints and coatings. Plastics often contain antioxidants, antistatic agents, thermal stabilizers, flame retardants, and additives that improve their water and air barrier properties. Because additives are introduced through physical mixing, they may leach over time, causing the degradation of the material and adverse effects on humans and the environment.